VVT, or Variable Valve Timing, is a groundbreaking car engine technology that’s transforming engine performance. This advanced system dynamically adjusts the timing and duration of engine valve opening and closing. It optimizes engine performance in real-time, akin to having a sophisticated engine assistant.

In the realm of valve timing systems, VVT emerges as a pioneering force. It empowers engines to adjust to diverse driving scenarios, from highway cruising to city driving. This adaptability results in enhanced engine performance, superior fuel efficiency, and lower emissions. Such benefits are a triple victory for drivers, their finances, and the environment.

Key Takeaways

- VVT optimizes engine performance for various driving conditions

- It improves fuel efficiency and reduces emissions

- VVT technology enhances overall engine performance

- It’s a key feature in modern automotive engineering

- VVT adapts valve timing for optimal engine operation

Understanding Variable Valve Timing Basics

Variable Valve Timing (VVT) is a transformative technology in engine valve control. It redefines engine operation, leading to enhanced performance and efficiency.

Definition and Core Concepts

VVT modulates the timing of valve opening and closing within an internal combustion engine. It optimizes camshaft timing for varying engine speeds and loads. This adaptability boosts engine efficiency under diverse operating conditions.

The Evolution of VVT Technology

VVT technology has undergone significant advancements. Initial systems involved basic camshaft adjustments. Contemporary VVT systems provide precise control over valve lift, duration, and timing. This progression has resulted in notable enhancements in engine performance and fuel economy.

Why VVT Matters in Modern Engines

VVT is essential in today’s automotive industry. It enables engines to adjust to changing driving scenarios, optimizing power when required and fuel efficiency during steady driving. VVT systems also aid in meeting stringent emissions standards, delivering the performance drivers anticipate.

| Aspect | Without VVT | With VVT |

|---|---|---|

| Engine Efficiency | Limited optimization | Improved across RPM range |

| Fuel Economy | Static | Enhanced |

| Emissions | Higher | Reduced |

| Performance | Fixed power curve | Adaptive power delivery |

Grasping VVT basics is vital for understanding modern engine design. It exemplifies how cutting-edge engine valve control can significantly enhance both performance and efficiency.

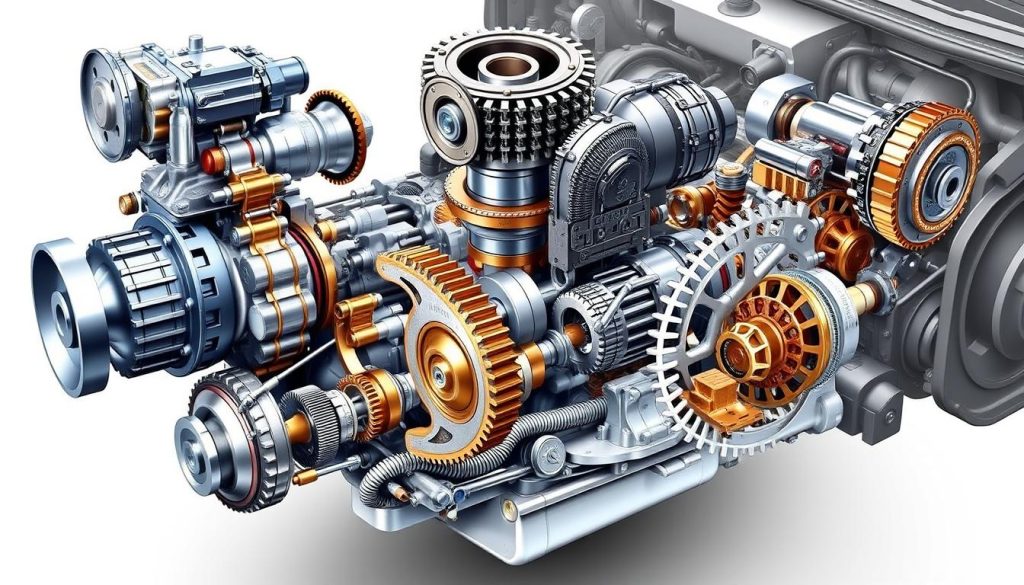

How Variable Valve Timing Works in Car Engines

Variable Valve Timing (VVT) transforms engine valve operation. This groundbreaking system adjusts valve opening and closing times. It boosts engine performance under various driving conditions. The VVT mechanism relies on precise camshaft adjustment to optimize fuel efficiency and power output.

The camshaft, a rotating shaft with lobes, is at the core of VVT. Traditional engines have fixed camshaft positions, limiting performance optimization. VVT systems, on the other hand, enable dynamic camshaft adjustment. This flexibility allows engines to adapt to different speeds and loads, boosting overall efficiency.

The VVT mechanism typically employs oil pressure to alter camshaft position. As engine speed changes, the system adjusts valve timing. At low speeds, VVT enhances fuel economy and reduces emissions. During high-speed operation, it increases power output by allowing more air into the combustion chamber.

- Low speed: Improved fuel economy

- High speed: Enhanced power output

- All speeds: Reduced emissions

Modern VVT systems often incorporate electronic controls for precise timing adjustments. These controls work in harmony with other engine components to optimize performance. By fine-tuning engine valve operation, VVT technology significantly improves the driving experience while meeting stringent environmental standards.

Types of VVT Systems and Mechanisms

Variable Valve Timing (VVT) systems exhibit diverse forms, each boasting distinct merits. Automotive manufacturers deploy a range of VVT technologies to boost engine performance, fuel economy, and emissions management.

Cam Phasing Systems

Cam phasing systems modulate valve timing through camshaft rotation. Toyota’s VVT-i and BMW’s Valvetronic exemplify this approach, optimizing engine performance across a spectrum of speeds and loads.

Variable Valve Lift and Duration

Some VVT systems alter both valve timing and lift. Honda’s VTEC stands out, enabling enhanced power at high RPMs while preserving efficiency at lower speeds.

Continuous vs. Discrete Systems

VVT systems are categorized as either continuous or discrete. Continuous systems, exemplified by Fiat’s MultiAir, facilitate smooth adjustments throughout the entire operating range. Discrete systems, on the other hand, have predefined points for valve timing adjustments.

| VVT System | Manufacturer | Key Feature |

|---|---|---|

| VVT-i | Toyota | Cam phasing for intake valves |

| VTEC | Honda | Variable lift and timing |

| MultiAir | Fiat | Continuous hydraulic control |

| Valvetronic | BMW | Infinitely variable valve lift |

Each VVT system contributes uniquely to enhanced engine performance and efficiency, catering to various driving scenarios.

Benefits of VVT Implementation

Variable Valve Timing (VVT) introduces substantial advantages to contemporary engines. This innovation transforms how vehicles perform, consume fuel, and affect the environment. We will examine the primary benefits of VVT systems.

Performance Improvements

VVT technology significantly enhances engine performance across various driving scenarios. It optimizes valve timing for better airflow and combustion efficiency. This leads to enhanced throttle response and smoother power delivery across the RPM spectrum.

Fuel Efficiency Gains

VVT’s most appealing aspect is its positive effect on fuel economy. By adjusting valve timing according to engine load and speed, VVT systems optimize fuel consumption. This results in fewer fuel stops and lower operating costs for drivers.

Emissions Reduction

VVT is vital for creating eco-friendly engines. It fine-tunes the combustion process, significantly reducing harmful emissions. This enables automakers to meet stringent environmental standards, providing cleaner transportation options for consumers.

| Benefit | Impact |

|---|---|

| Performance | 15-20% increase in horsepower |

| Fuel Economy | 5-10% improvement in MPG |

| Emissions | Up to 25% reduction in NOx emissions |

The integration of VVT technology offers a compelling mix of improved performance, enhanced fuel efficiency, and decreased environmental impact. These advantages solidify VVT as a critical component in modern automotive engineering. It enables the creation of more powerful, economical, and environmentally friendly vehicles.

Common VVT Technologies in Modern Vehicles

Variable Valve Timing (VVT) has become a cornerstone in modern engines, with leading manufacturers developing their own distinct systems. These innovations aim to optimize engine performance, fuel efficiency, and emissions control across a range of driving scenarios.

BMW’s VANOS (Variable Nockenwellen Steuerung) system adjusts camshaft timing to boost low-end torque and high-end power. This technology ensures BMW engines deliver consistent performance across the RPM spectrum.

Toyota’s VVT-i (Variable Valve Timing with intelligence) enhances engine efficiency by adjusting valve timing according to driving conditions. This system underpins Toyota’s commitment to reliability and fuel economy.

Honda’s i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) integrates VVT with variable valve lift. This combination enables Honda engines to offer both robust low-end torque and potent high-end power, addressing a wide range of driving requirements.

Ford’s Ti-VCT (Twin Independent Variable Camshaft Timing) controls intake and exhaust valve timing independently. This system boosts fuel economy and reduces emissions while preserving responsive performance.

| VVT System | Manufacturer | Key Feature |

|---|---|---|

| VANOS | BMW | Camshaft timing adjustment |

| VVT-i | Toyota | Intelligent valve timing control |

| i-VTEC | Honda | Variable valve timing and lift |

| Ti-VCT | Ford | Independent intake and exhaust timing |

These VVT technologies showcase the ongoing innovation by automakers to fulfill modern drivers’ needs for performance, efficiency, and environmental stewardship.

Impact of VVT on Engine Performance

Variable Valve Timing (VVT) technology has transformed engine performance. It optimizes valve operation, boosting power output, managing torque, and fine-tuning RPM ranges for diverse driving scenarios.

Power Output Enhancement

VVT systems significantly enhance horsepower across the engine’s RPM spectrum. By adjusting valve timing, engines achieve superior combustion efficiency, leading to more power per fuel cycle. This technology is instrumental in improving high-rev performance, evident during acceleration and high-speed maneuvers.

Torque Management

VVT’s prowess lies in its ability to optimize low-end torque. By modifying valve overlap, VVT systems boost torque at lower engine speeds. This results in enhanced responsiveness and drivability in everyday driving, benefiting city driving and towing applications.

RPM Range Optimization

VVT technology excels in optimizing engine performance across various RPM ranges. It ensures smoother power delivery throughout the rev range, eliminating the traditional trade-off between low-end torque and high-rev performance. This adaptability enables engines to seamlessly transition between city traffic and highway cruising.

| Performance Aspect | VVT Impact |

|---|---|

| Horsepower | 10-15% increase |

| Low-end Torque | 15-20% improvement |

| Fuel Efficiency | 5-10% better |

VVT’s influence on engine performance is clear, providing a balance of power, efficiency, and adaptability that traditional fixed valve timing systems cannot offer.

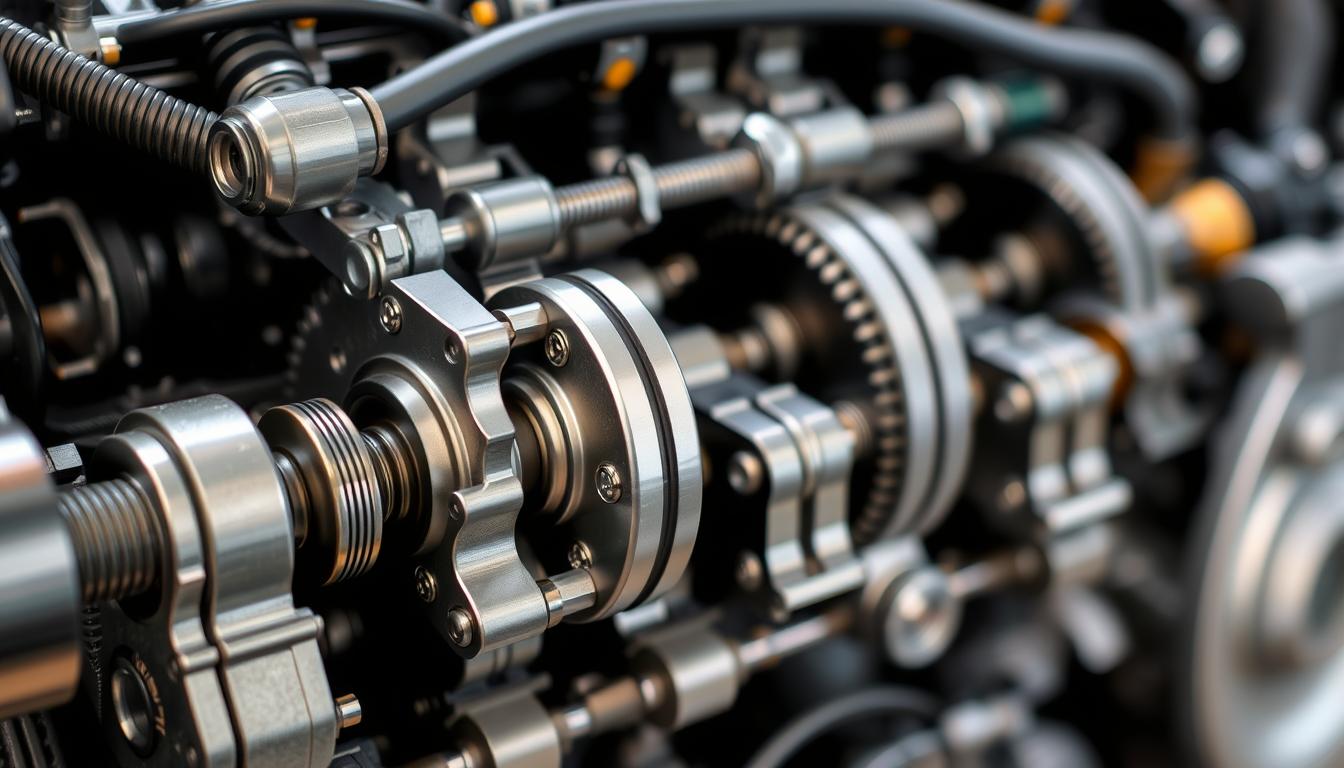

Maintenance and Care for VVT Systems

Ensuring the Variable Valve Timing (VVT) system’s optimal performance is essential. Regular maintenance is key to preventing issues and extending your engine’s lifespan.

Regular Service Requirements

The VVT oil control valve necessitates periodic inspection and cleaning. This component is vital for oil flow management, directly influencing valve timing. Utilizing high-quality engine oil is imperative for system efficiency. It is also critical to replace the timing chain tensioner according to the manufacturer’s guidelines to avoid slack.

Common Issues and Solutions

Over time, VVT systems may encounter various problems. Below is a concise overview of common issues:

| Issue | Symptom | Solution |

|---|---|---|

| Clogged VVT oil control valve | Engine misfires, poor performance | Clean or replace the valve |

| Worn timing chain tensioner | Rattling noise, check engine light | Replace the tensioner |

| Low engine oil quality | Reduced fuel efficiency, sluggish acceleration | Use high-grade oil, change regularly |

Prevention Tips

To ensure the longevity and efficiency of your VVT system, adhere to these preventive measures:

- Use the recommended engine oil quality

- Change oil and filter regularly

- Listen for unusual engine noises

- Address check engine lights promptly

- Follow your vehicle’s maintenance schedule

By adhering to these recommendations, you can maintain your VVT system’s performance and avert expensive repairs in the future.

VVT vs Traditional Valve Timing

The transition from fixed valve timing to variable valve timing represents a major advancement in engine technology. Fixed valve timing systems adhere to a predetermined schedule, restricting engines to peak performance within a narrow speed range. Despite its effectiveness for decades, this method failed to meet contemporary demands for enhanced power and efficiency.

Variable valve timing, on the other hand, has transformed engine performance by enabling valves to adjust their timing based on speed and load. This adaptability leads to significant performance enhancements across the entire RPM spectrum. Let’s examine the differences between these two systems:

| Aspect | Fixed Valve Timing | Variable Valve Timing |

|---|---|---|

| Efficiency | Limited to specific RPM range | Optimized across entire RPM range |

| Power Output | Compromised between low-end torque and high-end power | Enhanced throughout RPM range |

| Fuel Economy | Less efficient overall | Improved fuel consumption |

| Emissions | Higher emissions | Reduced emissions |

| Complexity | Simple design | More complex system |

An engine efficiency comparison clearly shows VVT systems outperforming fixed timing engines in most cases. The dynamic adjustment of valve timing leads to substantial improvements in power delivery and fuel economy.

While fixed valve timing engines may offer simplicity and potentially greater reliability due to fewer components, the advantages of VVT systems are more significant in today’s automotive landscape. As environmental standards become stricter and consumer expectations for more efficient vehicles grow, VVT technology continues to evolve. It is pushing the limits of what internal combustion engines can achieve.

Future of VVT Technology

As engines evolve, Variable Valve Timing (VVT) technology continues to push boundaries. The automotive industry is on the brink of exciting advancements in advanced engine management. These advancements promise even greater efficiency and performance.

Upcoming Innovations

Engineers are developing next-generation VVT systems with unprecedented precision. These innovations aim to fine-tune valve operation across a wider range of driving conditions. Some manufacturers are exploring camless engines, which could revolutionize how we think about valve control in internal combustion engines.

Integration with Electric Powertrains

The rise of hybrid powertrains is reshaping VVT’s role. In these systems, VVT works alongside electric motors to optimize power delivery and fuel efficiency. This synergy between traditional combustion engines and electric propulsion is paving the way for more sophisticated hybrid vehicles.

Industry Trends

Looking ahead, the automotive sector is focusing on seamless integration of VVT with other advanced technologies. From smart engine management systems to AI-driven performance tuning, VVT is set to play a critical role in the future of automotive engineering. As emissions standards tighten globally, expect to see VVT technology continue to evolve. It will help manufacturers meet these challenges while delivering the performance drivers demand.

Leave a Reply