Have you ever wondered how massive cruise ships glide effortlessly through the ocean or how power plants generate electricity to light up entire cities? The answer lies in a remarkable piece of engineering: steam turbine engines. 🚢💡

These powerful workhorses have been silently driving our modern world for over a century, yet many are unaware of their critical role. From powering industries to propelling ships and generating electricity, steam turbines are the unsung heroes behind much of our technological progress. But as we face growing environmental concerns and energy demands, it’s time to take a closer look at this technology. How efficient are they really? What impact do they have on our planet? And what does the future hold for steam turbine engines?

In this blog post, we’ll dive into the fascinating world of steam turbine engines, exploring their inner workings, wide-ranging applications, and the ongoing efforts to improve their efficiency. We’ll also examine their environmental impact and peek into the crystal ball to see what innovations might be on the horizon. So, let’s fire up our curiosity and embark on a journey through the realm of steam power! 🔥🔧

Understanding Steam Turbine Engines

Core principles of steam turbine technology

Steam turbine engines operate on the principle of converting thermal energy into mechanical energy. They utilize high-pressure steam to rotate blades connected to a shaft, generating power. Key advantages include:

- High efficiency

- Large power output

- Continuous operation

| Component | Function |

|---|---|

| Boiler | Generates steam |

| Turbine | Converts steam energy to mechanical energy |

| Generator | Produces electricity |

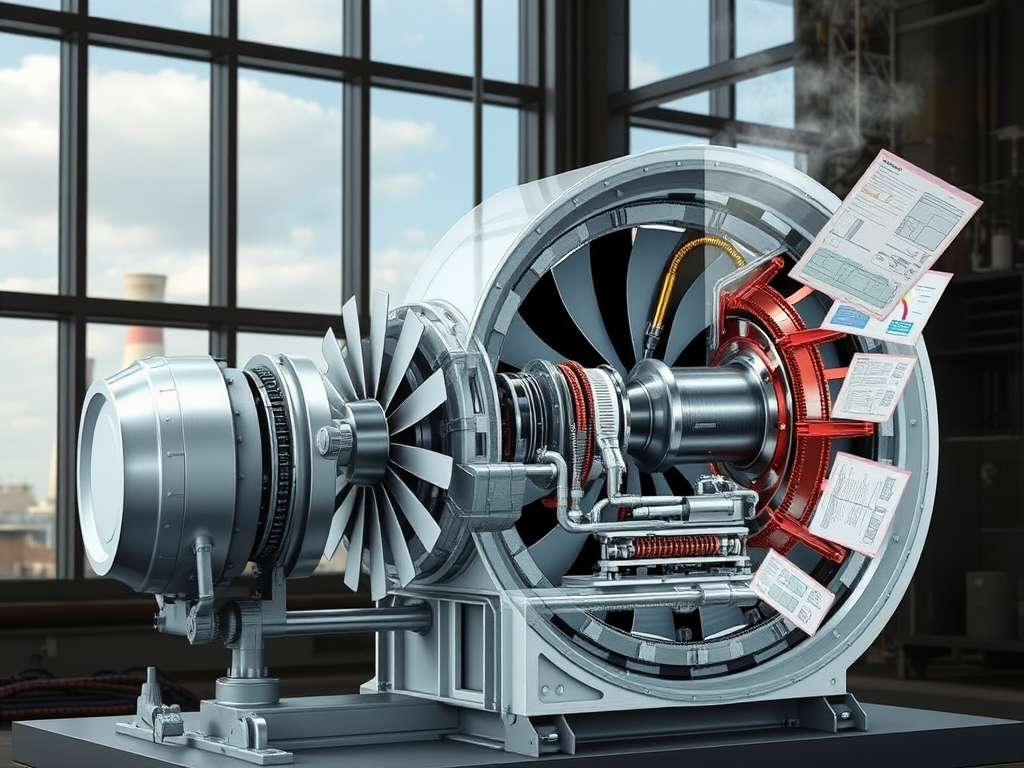

Key components and their functions

Steam turbines consist of several crucial components working together seamlessly:

- Rotor: The main rotating shaft

- Stator: Stationary blades that direct steam flow

- Casing: Houses and protects internal components

- Nozzles: Accelerate steam towards turbine blades

Applications Across Industries

A. Power generation and electricity production

Steam turbine engines are the backbone of power generation worldwide. They convert thermal energy from steam into mechanical energy, driving generators to produce electricity. Here’s a comparison of steam turbines with other power generation methods:

| Method | Efficiency | Scalability | Fuel Flexibility |

|---|---|---|---|

| Steam Turbines | High | Excellent | Very High |

| Gas Turbines | Moderate | Good | Limited |

| Hydroelectric | Very High | Limited | N/A |

B. Marine propulsion systems

In maritime applications, steam turbines power large vessels, offering:

- High power output

- Reliability in harsh conditions

- Long operational life

Now, let’s explore how steam turbines contribute to industrial manufacturing processes.

Efficiency Improvements in Steam Turbines

Advanced materials for enhanced performance

Innovative alloys and composites revolutionize steam turbine efficiency. High-temperature materials like nickel-based superalloys and ceramic matrix composites withstand extreme conditions, enabling higher operating temperatures and pressures.

| Material | Benefit |

|---|---|

| Superalloys | Increased heat resistance |

| Composites | Reduced weight, improved durability |

Optimizing blade design for maximum output

Aerodynamic advancements in blade design significantly boost turbine performance. 3D modeling and computational fluid dynamics optimize blade shapes, reducing losses and increasing power output. Advanced manufacturing techniques like 3D printing allow for complex geometries, further enhancing efficiency.

Environmental Impact and Sustainability

Emissions reduction strategies

Steam turbine engines have made significant strides in reducing emissions. Advanced combustion techniques and fuel selection play crucial roles in minimizing environmental impact. Here’s a comparison of emission reduction strategies:

| Strategy | Effectiveness | Cost |

|---|---|---|

| Low-NOx burners | High | Moderate |

| Fuel switching | Medium | Variable |

| Carbon capture | Very high | High |

Water consumption and conservation measures

Efficient water management is essential for sustainable steam turbine operations. Closed-loop cooling systems and wastewater recycling help conserve this precious resource. Implementing these measures not only reduces environmental impact but also improves overall plant efficiency.

Future Trends and Innovations

Supercritical and ultra-supercritical steam cycles

Supercritical and ultra-supercritical steam cycles represent cutting-edge advancements in steam turbine technology. These systems operate at higher temperatures and pressures, significantly improving efficiency and power output.

| Cycle Type | Temperature | Pressure | Efficiency |

|---|---|---|---|

| Subcritical | <540°C | <22 MPa | ~35-38% |

| Supercritical | 540-580°C | 22-25 MPa | ~42-45% |

| Ultra-supercritical | >580°C | >25 MPa | >45% |

Integration with renewable energy sources

• Solar thermal power plants

• Geothermal steam systems

• Biomass-fired steam generators

Steam turbine engines continue to play a crucial role in various industries, from power generation to marine propulsion. Their versatility, reliability, and ongoing technological advancements make them an indispensable part of our modern infrastructure. As we’ve explored, these engines have come a long way in terms of efficiency and environmental impact, with innovations driving their performance to new heights.

Looking ahead, the future of steam turbine engines appears promising. With a focus on sustainability and the integration of smart technologies, we can expect to see even more efficient and environmentally friendly designs. As industries and governments worldwide strive for cleaner energy solutions, steam turbine engines will undoubtedly evolve to meet these challenges, ensuring their relevance for generations to come.

Leave a Reply