Like the blood in our body, the lubricating oil in our vehicle’s engine needs to be clean to do its job well and contribute to the health of the engine and vehicle.

The cleaner it is, the better the job it will do.

Although it is normal for the oil to get dirty and turn black (which means that its detergent action is working), multiple factors exceed its capacity, which reduces its useful life and effectiveness, such as:

Table of Contents

ToggleWEAR OF MOVING PARTS

The engine’s moving parts are constantly in motion and rubbing against each other, generating small particles of metal and other materials that break off and enter the oil, contaminating it.

COMBUSTION

During the combustion process in the engine, small amounts of gases and particles (soot, carbon) leak into the oil pan. These contaminants, such as soot and combustion byproducts, can mix with the oil and foul it.

AIR INTAKE

When the engine is running, unfiltered air can enter (due to an old, worn, or failing filter or ground conditions) and carry dust, grime, and various particles in the oil.

HEAT AND OXIDATION

Engine oil is exposed to extreme heat conditions due to engine operating temperatures. This heat causes the oil to degrade and oxidize, forming sludge deposits and fouling it with other byproducts.

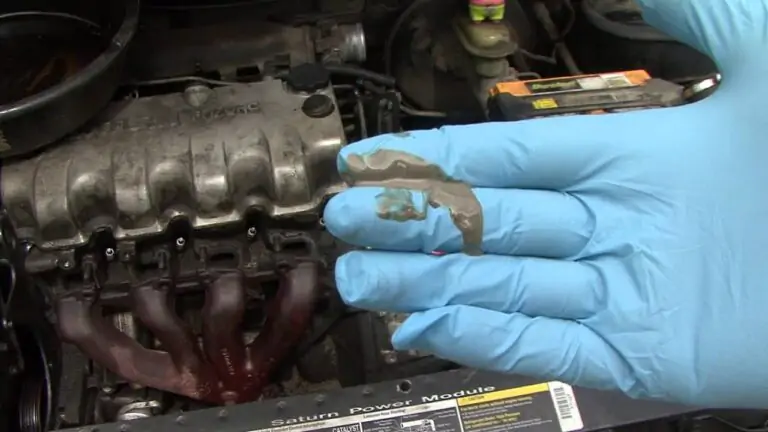

LIQUIDS

Water may accumulate inside the engine due to condensation, or coolant may leak. These liquids can emulsify with the oil, contaminating it and decreasing its lubrication capacity.

All these contaminants reduce the action of the lubricating oil in the engine, causing:

- Premature parts wear: Dirt particles and contaminants in the oil increase friction between moving engine parts, leading to accelerated wear of components such as pistons, rings, camshafts, bearings, and cylinders.

- Reduced lubrication: Oil contamination decreases the lubricating capacity of the oil, which increases friction and heat in the engine. This can lead to increased wear on parts and engine overheating.

- Deposit Formation: Contaminants in the oil can contribute to the formation of sludge and varnish deposits. These deposits can clog lubrication passages, damage moving parts, and contaminate fresh lubricating oil.

- Reduced engine efficiency: Contaminated oil can negatively affect engine performance, reducing power, poor acceleration, and increased fuel consumption.

- Engine overheating: Lack of oil cooling capacity due to contamination can cause the engine to overheat, which can cause serious damage such as deformation of metal parts.

- Acceleration of oil aging: Contaminants in the oil can accelerate its degradation and oxidation, which decreases its useful life and its ability to perform its lubricating function.

- Loss of power and performance: Contaminated oil can negatively affect engine response and power, making the vehicle less safe and efficient on the road.

How can the contamination of lubricating oil be reduced and the lubricating oil kept clean for longer?

Keeping it clean for longer is possible, ensuring that it fulfills its lubricating role effectively.

To do this, it is essential:

- Use the oil recommended by the manufacturer

- Perform regular oil changes according to the manufacturer’s recommendations

- Regularly check the oil level

- Use quality oil filters and change them at the recommended times

- Avoid starting your car and letting it idle for extended periods in cold weather to minimize wear and tear. Instead, wait a few moments after starting for the oil to circulate before driving gently.

- Keep the combustion system clean using quality fuel and system cleaner additives.

- Carry out periodic checks and maintenance on the engine.

In addition, regularly using products helps to internally clean the engine of all kinds of contaminants that affect the useful life of the lubricant and that do not come out completely with the oil change.

These products’ anti-friction properties keep your engine protected at all times, even during friction and extreme temperatures, such as poor lubrication due to contamination of the lubricating oil or cold starting.

Remember that with every oil change and every decision you make to care for your vehicle, you are paving the way to a healthier engine, exceptional performance, and a safe, quiet trip without technical difficulties.

How to take care of the lubrication system?

Due to the above, it is essential to ensure that it is in optimal condition so as not to affect the productivity or reliability of the equipment. Here we share some recommendations to help you take care of it:

Storage and handling of lubricants

Lubricants become vulnerable to contamination during storage and especially when moved. Even a sealed container can be susceptible to contamination since moisture and dust lodged around the lid can enter the interior due to temperature changes or when it is opened.

To reduce lubricant contamination during storage we recommend:

- Store lubricants in well-closed, ventilated, and ideally covered spaces with low exposure to dust, excess humidity, or water.

- Place product labels visible to avoid incorrect applications

- Close caps immediately after use

Maintenance programs

Boost equipment life! Proactive maintenance with improved lubrication practices optimizes performance and identifies issues for peak productivity.

This approach also crucially protects machinery from contamination, which is a major cause of lubrication system failure and can lead to costly repairs.

Periodic monitoring and conditioning

Building on the importance of clean oil, oil analysis emerges as a powerful tool for monitoring its condition. It helps identify the contaminants present and their properties, ultimately providing valuable information to extend the lifespan of your machinery.

Beyond regular oil changes, periodically conditioning the lubrication system offers additional benefits. This practice helps maintain cleanliness throughout the system’s lifecycle, including before initial use, during service intervals, oil changes, equipment installation, and maintenance tasks.

These recommendations are just a few proactive ways to help protect your lubrication system from contamination. Identifying and following best practices can take you one step closer to improving productivity.

Leave a Reply