Maintaining your diesel car engine is essential for its longevity and performance. Diesel engine care is distinct from gasoline engines, necessitating proper vehicle maintenance. Regular engine upkeep not only extends your car’s life but also saves you money in the long run.

Diesel engines are renowned for their durability and efficiency. They demand specific care to preserve their robust nature. From oil changes to fuel system checks, each maintenance aspect is critical for your engine’s health. Grasping these unique needs ensures your diesel car operates smoothly for years.

Key Takeaways

- Diesel engines need specific maintenance different from gasoline engines

- Regular upkeep extends engine life and improves performance

- Proper diesel engine care includes routine fluid checks and replacements

- Timely maintenance prevents costly repairs and breakdowns

- Understanding your diesel engine’s needs is critical for effective care

Understanding Diesel Engine Basics and Maintenance Requirements

Diesel engines power a significant number of vehicles on American roads. They differ from gasoline engines in several critical aspects. Understanding these differences is essential for proper maintenance of diesel vehicles.

Diesel vs Gasoline Engines

Diesel engines operate through compression ignition, contrasting with gasoline engines that use spark ignition. Diesel engines compress air to extremely high temperatures, followed by fuel injection. In contrast, gasoline engines mix fuel and air before compression. This distinction often results in diesel engines being more fuel-efficient and producing greater torque.

Common Diesel Engine Components

Diesel engines possess unique components not found in gasoline engines. These include:

- Fuel injection pump

- Glow plugs

- Turbocharger

- Intercooler

Recognizing these components is vital for early detection of any issues.

Regular Maintenance Schedules

Adherence to a strict maintenance schedule is imperative for diesel engines. Regular maintenance not only prevents costly repairs but also extends the engine’s lifespan. Key tasks include:

| Maintenance Task | Frequency |

|---|---|

| Oil changes | Every 5,000-7,000 miles |

| Fuel filter replacement | Every 10,000-15,000 miles |

| Air filter check | Every 15,000-30,000 miles |

Adhering to these guidelines ensures diesel engines operate efficiently for extended periods. Regular maintenance enhances fuel efficiency and minimizes emissions.

Essential Fluid Checks and Replacements

Proper fluid maintenance is vital for your diesel engine’s smooth operation. Regular inspections and timely fluid replacements are essential for peak performance and longevity.

Engine Oil Selection and Change Intervals

Opting for the correct engine oil is imperative for diesel engines. Seek oils formulated for diesel use, with the appropriate viscosity grade. Most diesel engines necessitate oil changes every 5,000 to 7,500 miles. Always consult your owner’s manual for precise intervals.

Coolant Maintenance and Testing

Coolant is indispensable in preventing engine overheating and freezing. It is advisable to test your coolant annually and replace it every 30,000 to 60,000 miles. Utilize a coolant designed for diesel engines to safeguard against corrosion and cavitation.

Fuel Filter Replacement Guidelines

Fuel filters are critical in capturing contaminants that could harm your engine. Adhere to your vehicle’s schedule for replacement, usually every 10,000 to 15,000 miles. Clean fuel enhances engine performance and fuel efficiency.

| Fluid | Check Interval | Replacement Interval |

|---|---|---|

| Engine Oil | Monthly | 5,000 – 7,500 miles |

| Coolant | Every oil change | 30,000 – 60,000 miles |

| Fuel Filter | Every oil change | 10,000 – 15,000 miles |

These guidelines serve as a general framework. Always consult your vehicle’s manual for specific fluid maintenance advice. By diligently attending to these fluids, your diesel engine will maintain efficiency for extended periods.

Diesel car engine Performance Monitoring

Monitoring your diesel engine’s performance is essential for its longevity and efficiency. Modern diagnostics have streamlined tracking key performance indicators and identifying issues early. This proactive approach prevents problems from becoming severe.

An onboard diagnostic (OBD) scanner is a powerful tool for monitoring. It connects to your vehicle’s OBD port, providing real-time data on engine parameters. Key indicators to monitor include:

- Fuel pressure

- Exhaust gas temperature

- Boost pressure

- Engine load

Regularly checking these metrics helps identify trends and catch problems early. For example, a drop in fuel pressure might signal a failing fuel pump. High exhaust temperatures could indicate issues with the emission control system.

Today’s advanced monitoring tools integrate with smartphones, allowing you to track engine performance anywhere. These apps offer customizable dashboards and alert systems. They make it simpler to monitor your diesel engine’s health.

| Performance Indicator | Normal Range | Potential Issue if Out of Range |

|---|---|---|

| Fuel Pressure | 30-60 PSI | Fuel pump or injector problems |

| Exhaust Gas Temperature | 300-1200°F | Emission system malfunction |

| Boost Pressure | 7-30 PSI | Turbocharger issues |

| Engine Load | 20-80% | Mechanical or fuel system problems |

Utilizing these diagnostics and monitoring tools ensures your diesel engine runs at its best. This can save you from expensive repairs in the future.

Air Filtration System Maintenance

Maintaining your diesel engine’s air filtration system is essential for its performance and longevity. A well-maintained system guarantees clean air intake, safeguarding your engine from harmful contaminants.

Air Filter Inspection and Replacement

Regular inspections of the air filter are imperative. Examine for signs of dirt accumulation or damage every 15,000 to 30,000 miles. Replace the filter when it appears dirty or clogged. A clean air filter enhances fuel efficiency and boosts engine power.

Turbocharger Maintenance Tips

Turbochargers are vital for boosting engine performance but require diligent care. Monitor for oil leaks and unusual sounds. Utilize high-quality oil and adhere to the recommended change intervals. Allow your engine to idle for a minute before shutting it off to safeguard the turbocharger bearings.

Intake System Cleaning

A pristine intake system is critical for optimal airflow. Employ a specialized cleaner to eliminate carbon deposits from intake valves and manifolds. This practice preserves engine efficiency and minimizes emissions.

- Inspect air filter every 15,000-30,000 miles

- Check turbocharger for leaks and noises

- Clean intake system to remove carbon deposits

Adhering to these maintenance practices ensures your diesel engine operates at its best. Regular upkeep of the air filtration system, turbocharger, and intake system guarantees prolonged engine performance and efficiency.

Fuel System Care and Management

Ensuring your diesel engine’s fuel system remains in peak condition is essential for its performance and longevity. Adequate care guarantees the delivery of clean fuel, averting the need for expensive repairs.

Preventing Fuel Contamination

Initiating fuel quality maintenance with preventive measures is key. Opt for reputable fuel stations and steer clear of filling up when tanker trucks are replenishing station tanks. This strategy minimizes the chance of sediment contamination. Incorporating a fuel water separator is also advisable, as it captures contaminants before they can harm your engine.

Injector Maintenance

Injector upkeep is indispensable for diesel engine health. It is advisable to clean injectors every 30,000 miles or as per your vehicle’s manufacturer guidelines. Employing high-quality fuel additives is beneficial for maintaining injector cleanliness between maintenance intervals. Should you encounter issues such as rough idling or diminished fuel efficiency, it’s likely time for injector service.

Fuel Tank Care

Effective fuel tank maintenance is critical to prevent rust and bacterial proliferation. Ensure your tank remains at least half full to reduce condensation. Annual draining of water from the tank is also recommended. For extended vehicle storage, incorporating a fuel stabilizer is imperative to prevent fuel degradation.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Fuel Filter Change | Every 15,000-20,000 miles | Ensures clean fuel delivery |

| Injector Cleaning | Every 30,000 miles | Improves fuel efficiency |

| Tank Draining | Annually | Prevents water accumulation |

By consistently addressing these fuel system care elements, your diesel engine will continue to operate efficiently and reliably for extended periods.

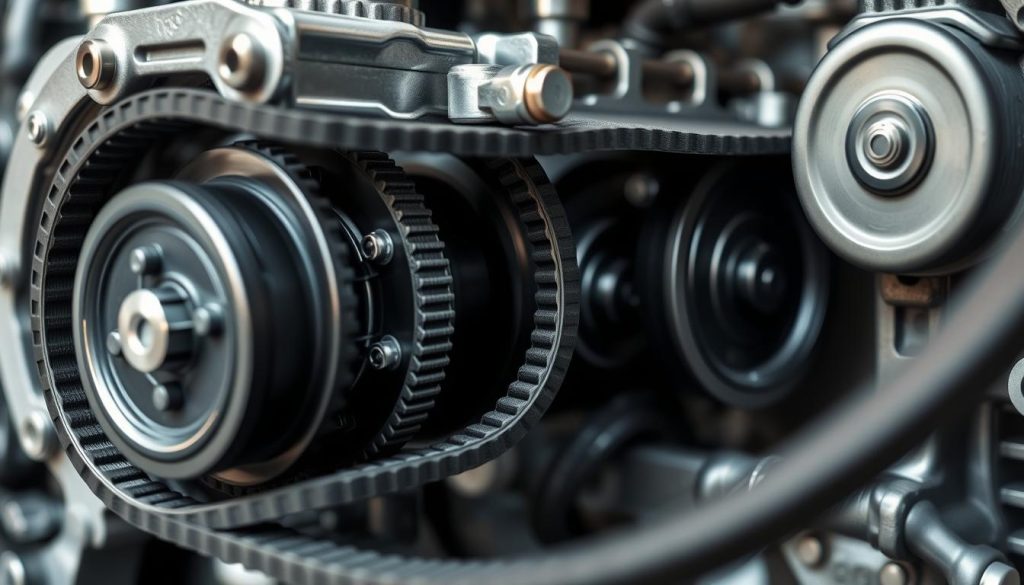

Belt and Timing System Upkeep

Maintaining your diesel engine’s belt and timing system is essential for peak performance. Regular care of the timing belt, serpentine belt, and belt tensioner can avert expensive repairs and prolong your engine’s lifespan.

The timing belt synchronizes the crankshaft and camshaft’s rotation, ensuring accurate valve timing. Most manufacturers advise replacing it every 60,000 to 100,000 miles. Neglecting this can result in engine failure if the belt breaks.

Your serpentine belt powers various engine components like the alternator, power steering pump, and air conditioning compressor. Look for signs of wear such as cracks, fraying, or glazing. Replace it when necessary to prevent sudden failures.

The belt tensioner keeps the serpentine belt at the correct tension. A failing tensioner can cause belt slippage or premature wear. Listen for unusual noises and check for smooth tensioner arm movement during inspections.

- Inspect belts visually every 3,000 miles

- Check tensioner operation during routine maintenance

- Replace timing belt according to manufacturer’s schedule

- Consider replacing the water pump with the timing belt

Regular maintenance of these components ensures your diesel engine operates smoothly and efficiently. Neglecting this critical aspect of engine care can lead to unexpected repairs and compromise your vehicle’s reliability.

Emission Control System Maintenance

Ensuring your diesel car’s emissions control system remains in optimal condition is essential. It not only enhances performance but also ensures environmental compliance. Regular upkeep of critical components is vital for maintaining a vehicle that operates efficiently and cleanly.

DPF Cleaning and Regeneration

The Diesel Particulate Filter (DPF) captures soot particles from exhaust gases. It necessitates cleaning to maintain its functionality. Modern diesel cars often employ automatic regeneration, which burns off trapped particles during extended highway drives. For vehicles that do not frequently engage in long-distance travel, manual regeneration becomes imperative.

EGR System Maintenance

The Exhaust Gas Recirculation (EGR) system is designed to diminish nitrogen oxide emissions. It can, over time, accumulate carbon deposits, impacting engine performance. Ensuring the EGR valve and passages are regularly cleaned is critical for maintaining its optimal functionality.

AdBlue System Care

AdBlue, a urea-based solution, is instrumental in breaking down harmful nitrogen oxides in diesel exhaust. It is imperative to maintain the AdBlue tank’s level and inspect for any signs of leaks or crystallization around the filler cap. Adherence to the vehicle’s maintenance schedule for replacing the AdBlue filter is also necessary.

| Component | Maintenance Task | Frequency |

|---|---|---|

| DPF | Regeneration | As needed or every 300-600 miles |

| EGR | Cleaning | Every 50,000 miles |

| AdBlue | Refill | Every 3,000-10,000 miles |

By diligently maintaining these emissions control systems, you ensure your diesel car operates efficiently and cleanly for an extended period.

Common Maintenance Mistakes to Avoid

Avoiding maintenance errors is essential for the longevity of your diesel engine. We will examine common pitfalls and strategies to circumvent them.

Using Wrong Fluids and Parts

Utilizing incorrect parts or fluids can cause severe engine damage. Always refer to your owner’s manual for the correct specifications. While cost-effective, non-OEM parts often lead to expensive repairs down the line.

Ignoring Warning Signs

Warning signs are your engine’s way of alerting you to issues. Unusual noises, smoke, or dashboard lights should never be dismissed. Addressing these promptly can prevent major breakdowns and costly repairs.

Skipping Scheduled Maintenance

Regular maintenance is vital for diesel engines. Neglecting oil changes, filter replacements, or tune-ups can result in decreased performance and a shorter engine lifespan. Adhere to your vehicle’s recommended service schedule to sidestep these problems.

| Maintenance Error | Potential Consequence | Prevention |

|---|---|---|

| Using wrong oil | Engine wear, reduced efficiency | Use manufacturer-recommended oil grade |

| Ignoring check engine light | Increased damage, costly repairs | Address warning signs promptly |

| Neglecting air filter | Poor fuel economy, reduced power | Replace air filter regularly |

By steering clear of these common maintenance errors, you ensure your diesel engine operates efficiently and reliably for years.

Conclusion

Proper diesel maintenance is essential for maintaining your engine’s performance. Adhering to the guidelines outlined in this article can significantly extend your engine’s lifespan and prevent expensive repairs. It is imperative to regularly change the oil, replace the fuel filter, and clean the air system for optimal performance.

Diesel engines require specific care due to their unique nature. Utilizing the correct fluids and components is critical. Ignoring warning signs or neglecting scheduled maintenance can lead to significant issues. By taking these simple precautions, you can avoid unnecessary expenses and headaches in the future.

Consistent maintenance of your diesel engine yields substantial benefits. These include enhanced fuel efficiency, reduced emissions, and superior overall performance. By diligently attending to your engine’s needs, you can ensure a smoother, more reliable driving experience for years to come.

Leave a Reply