High-revving engines are internal combustion engines designed to rotate and work at a relatively high speed, generally above 6000 revolutions per minute (RPM).

Revolutions per minute (RPM) is the number of turns the crankshaft makes in one minute, and measures how fast the engine is running.

One of the main attractions of this type of engine and its reasons for existence is that it can produce a good amount of power in a small space. They are highly efficient, which makes them have a wide variety of applications:

- Racing and competition vehicles (cars, motorcycles, boats, aircraft, etc.)

- Daily use vehicles

- Military vehicles

- Working machinery

Among many others.

Their usefulness is based on the fact that they have greater power and better efficiency compared to low-revving engines.

Table of Contents

ToggleBut how does it work?

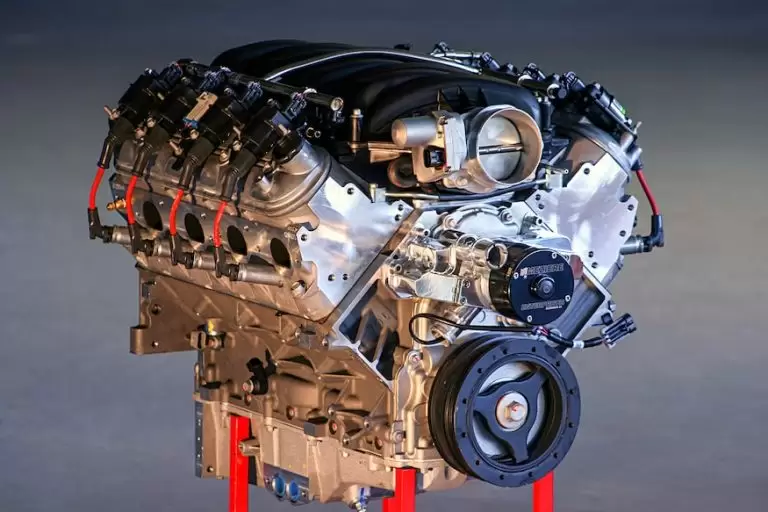

A high-revving engine works by combining air and fuel in the combustion chamber and subsequently igniting the mixture to generate power.

The main difference between a high-revving engine and a low-revving engine is the speed at which the pistons move and the speed at which combustion occurs.

In a high-revving engine, the pistons move faster than in a low-revving engine, which means that combustion occurs faster and more times per minute.

This is possible thanks to its design, which gives it unique characteristics:

Better air and fuel flow

High-revving engines have better air and fuel flow, allowing for better fuel-air mixing and more complete combustion.

Better compression ratio

High-revving engines typically have a higher compression ratio, allowing more energy to be extracted from each burst of fuel.

Higher combustion rate

High-revving engines have a higher combustion rate. This means more fuel can be burned in a shorter period of time.

Less moving mass

By having a higher rotational speed, high-revving motors have less moving mass than low-revving motors, reducing inertia and allowing for greater efficiency and power.

These unique design qualities make high-revving motors attractive for a multitude of applications. They have more power, better performance, lower weight and size, and are more flexible than low-revving motors.

However, these attractive qualities also make them more prone to failure, so they require additional care and maintenance to ensure good operation.

Why are they more prone to failure?

For several reasons, including:

- Increased Friction: Due to high rotation, moving components experience increased friction levels, generating heat and wear on the components. If the engine is not kept properly lubricated, friction can cause damage to components and result in failure.

- Higher pressure and temperature: Due to high rotation, high-revving engines experience higher pressures and temperatures, which can damage key components such as pistons, bearings, and rings.

- Increased vibration: High rotation can also cause increased vibration, which can wear on key components such as connecting rods and bearings.

- Lower tolerance for errors: High-revving engines are more sensitive to irregularities in operation, such as combustion problems or lack of lubrication, which can result in mechanical failure.

- Smaller, more fragile components: Due to their small size, high-revving engine components are smaller and more fragile than low-revving engine components, increasing the likelihood of failure.

In high-revving engines, the higher the RPM, the greater the engine power, but at the same time, greater friction, temperature, and wear.

What can be done to protect this class of engines?

The following recommendations can help a high-revving engine last longer and perform well:

Change the oil regularly

Oil is a key component for engine lubrication and cooling, so it is important to change it regularly according to the manufacturer’s recommendations.

Perform regular maintenance

Including checking and replacing air and fuel filters, checking spark plugs, and checking cooling and lubrication systems.

Use the right gasoline

It is crucial to use the gasoline quality recommended by the manufacturer. This ensures proper fuel-air mixture and prevents engine damage.

Improve cooling

Ensure the cooling system is in good condition and working properly to keep the engine cool and prevent overheating.

Avoid overloading the motor

Do not overload the engine, especially when it is hot, always try to use the gear that the engine needs. Otherwise this can cause overload and seriously damage the motor in the long term.

Avoid exceeding the recommended RPM

Drive smoothly and avoid harsh acceleration or exceeding the recommended RPM. This will help extend the engine’s life and improve its efficiency.

Use a suitable transmission

It is important to use a transmission that matches the characteristics of the high-revving engine and allows it to operate efficiently.

Check the suspension

The suspension is also important for the proper functioning of the high-revving engine. A poor suspension can affect the vehicle’s stability and handling, which can be detrimental to the engine. Engines that operate at high revolutions per minute provide a great combination of power and efficiency. Still, they must be maintained with extra care to ensure longevity and performance.

Leave a Reply