Car enthusiasts and racing aficionados frequently discuss NOS, yet its true impact remains unclear. Nitrous oxide systems deliver a remarkable performance enhancement, transforming ordinary vehicles into high-speed machines. This potent gas significantly elevates horsepower and torque, achieving these gains almost instantaneously.

In the racing arena, where every millisecond is critical, NOS stands out as a key component. It serves as a potent tool, enabling engines to reach their peak performance levels. This is invaluable on both drag strips and street races, solidifying NOS as a preferred choice for those seeking enhanced performance.

Key Takeaways

- NOS provides a quick and significant boost to car engine performance

- It’s widely used in racing for its ability to increase horsepower and torque

- NOS works by adding extra oxygen to the combustion process

- The performance gain from NOS is immediate and noticeable

- Proper installation and use of NOS are critical for safety and engine longevity

Understanding Nitrous Oxide Systems in Racing

Nitrous oxide systems have transformed the racing landscape, significantly boosting engine performance. These systems leverage nitrous oxide’s unique properties to enhance combustion and elevate power output.

Chemical Properties of Nitrous Oxide

Nitrous oxide, a colorless, non-flammable gas, is composed of two nitrogen atoms and one oxygen atom. At elevated temperatures, it decomposes, liberating oxygen that fuels combustion. This characteristic renders it highly suitable for racing applications.

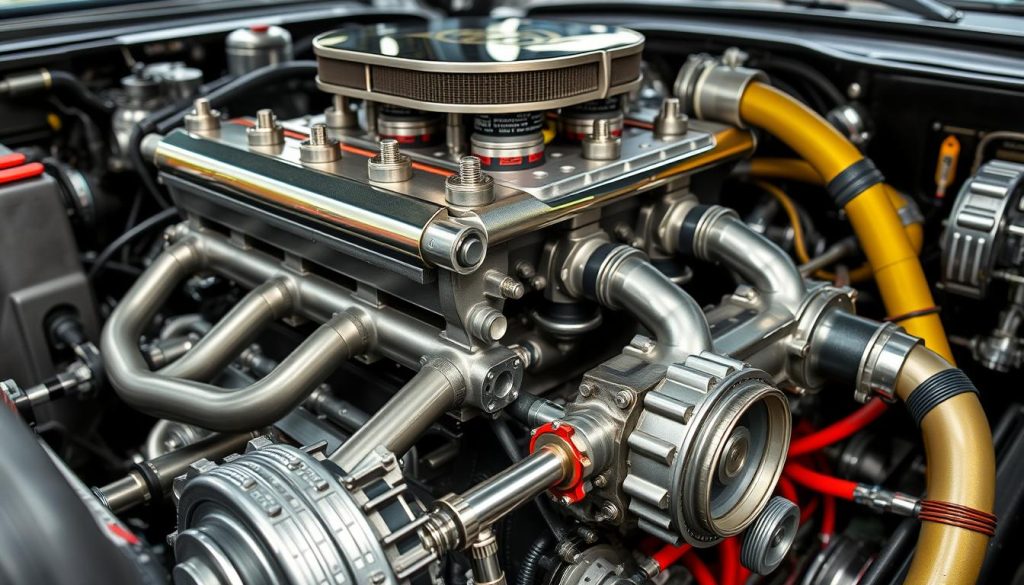

Basic Components of a NOS System

A typical nitrous oxide system comprises several critical NOS components:

- Nitrous bottle

- Solenoid valves

- Fuel lines

- Nozzles or injectors

- Activation switch

These components collaborate to deliver a precise blend of nitrous oxide and fuel to the engine. This results in a notable power enhancement.

Types of Nitrous Systems Available

There are three primary types of nitrous systems employed in racing:

- Wet nitrous system: Injects both nitrous oxide and additional fuel

- Dry nitrous system: Injects only nitrous oxide, relying on the engine’s existing fuel system

- Direct port injection: Delivers nitrous oxide directly to each cylinder for maximum efficiency

Each system offers distinct advantages, and the selection hinges on the specific racing application and engine configuration. Racers frequently experiment with different setups to achieve the optimal balance between power and reliability.

The Science Behind NOS Power Boost

Nitrous oxide systems (NOS) transform car engine performance through complex scientific processes. These systems utilize nitrous oxide to boost combustion efficiency and significantly increase power.

Oxygen Release Process

Upon entering the engine, nitrous oxide decomposes into oxygen and nitrogen. This decomposition releases additional oxygen into the combustion chamber. This extra oxygen enables a richer fuel mixture, leading to a substantial power increase.

Combustion Enhancement

The extra oxygen from NOS supercharges combustion. This enhanced combustion results in more explosive force within the engine cylinders. As a result, pistons are pushed down with increased force, leading to higher horsepower and torque.

Temperature Control Effects

Nitrous oxide is critical for engine cooling. As it transitions from liquid to gas, it absorbs heat from its surroundings. This cooling effect helps maintain optimal engine temperatures during high-performance operations, preventing overheating and damage.

| Factor | Effect on Engine | Performance Impact |

|---|---|---|

| Oxygen Release | Enriches fuel mixture | Increases power output |

| Combustion Enhancement | More explosive force | Boosts horsepower and torque |

| Temperature Control | Cools engine components | Prevents overheating, maintains performance |

Understanding these scientific principles is key for racers and enthusiasts to maximize NOS benefits. It ensures safe and efficient engine operation.

Car Engine Modifications Required for NOS

Installing a nitrous oxide system necessitates meticulous engine modifications to accommodate the augmented power output. We will examine the fundamental alterations required for a secure and efficient NOS configuration.

Engine reinforcement is the bedrock of NOS preparation. Enhancing internal components such as pistons, connecting rods, and crankshafts is imperative. These components must endure the augmented stress from elevated combustion pressures.

Fuel system enhancements are critical for NOS performance. The integration of larger fuel injectors and a high-flow fuel pump guarantees sufficient fuel supply. This measure prevents lean conditions, which can precipitate engine damage.

Modifications to the ignition system are indispensable for reliable NOS operation. The upgrade to colder spark plugs and a more potent ignition coil facilitates the management of heightened cylinder pressures.

| Modification | Purpose | Components |

|---|---|---|

| Engine Reinforcement | Withstand higher pressures | Forged pistons, stronger connecting rods |

| Fuel System Upgrades | Ensure proper fuel delivery | High-flow injectors, upgraded fuel pump |

| Ignition System Modifications | Manage increased cylinder pressures | Colder spark plugs, high-output ignition coil |

It is vital to remember that these modifications necessitate meticulous planning and the expertise of a professional installer. Omitting any step can result in catastrophic engine failure. Always seek the counsel of a professional before embarking on NOS installation.

Installation Process and Safety Considerations

NOS installation necessitates meticulous planning and execution. Safety measures are imperative when handling nitrous oxide systems. We will examine the essential components of setting up and maintaining a NOS system.

Professional Installation vs DIY

Some car enthusiasts choose DIY NOS installation, while others prefer professional tuning. Professionals guarantee correct system integration and minimize risks from incorrect setup. DIY setups can be cost-effective but demand significant knowledge and precision.

| Aspect | Professional Installation | DIY Installation |

|---|---|---|

| Cost | Higher initial investment | Lower upfront cost |

| Expertise | Guaranteed professional knowledge | Requires personal research and skill |

| Time | Quicker installation | May take longer to complete |

| Warranty | Often includes warranty | No professional warranty |

Safety Equipment Requirements

Essential safety equipment is a must for NOS systems. This includes fire-resistant clothing, gloves, and adequate ventilation. Regular system inspections and maintenance are critical to prevent leaks and ensure peak performance.

Emergency Shutdown Systems

An emergency cutoff switch is a vital safety feature. It enables quick system shutdown in case of malfunction. Proper placement ensures easy access during emergencies. Regular testing of the emergency cutoff system is vital for maintaining safety standards.

“Safety isn’t expensive, it’s priceless. Always prioritize proper safety measures when working with NOS systems.”

Remember, professional guidance can significantly enhance safety and performance when dealing with nitrous oxide systems. Prioritize safety at every step of the NOS installation and usage process.

Performance Gains and Power Output

NOS systems deliver notable performance enhancements for both car enthusiasts and racers. The horsepower increase can reach up to 50%, leading to significant torque gains and acceleration improvements. This makes NOS a favored choice for those involved in drag racing.

| Vehicle Type | Horsepower Increase | Torque Boost | 0-60 mph Improvement |

|---|---|---|---|

| Muscle Car | 75-150 HP | 80-120 lb-ft | 0.5-1.0 seconds |

| Sport Compact | 50-100 HP | 60-90 lb-ft | 0.3-0.7 seconds |

| Truck | 100-200 HP | 100-150 lb-ft | 0.7-1.2 seconds |

The extent of these gains depends on several factors, including engine size, NOS system type, and tune. For drag racing enthusiasts, the acceleration improvement can shave off critical tenths of a second from quarter-mile times. It’s vital to remember that while NOS offers instant power, proper tuning and installation are essential to maximize performance and prevent engine damage.

Common Risks and Engine Damage Concerns

Utilizing nitrous oxide systems (NOS) in vehicles can enhance performance, yet it poses significant risks. Engine damage is a prevalent concern among NOS users. Grasping these risks is essential for safeguarding your investment and ensuring safe operation.

Potential Engine Failures

NOS can precipitate severe engine malfunctions if not deployed correctly. Overheating frequently arises from an imbalanced fuel mixture. Detonation, or engine knock, occurs when combustion timing is misaligned. In extreme scenarios, piston failure may ensue due to heightened heat and pressure.

Prevention Measures

Proper tuning is imperative to avert engine damage. This entails:

- Adjusting fuel mixture for optimal performance

- Setting correct ignition timing

- Installing stronger internal components

- Utilizing high-quality fuel and oil

Warning Signs to Watch

Be vigilant for these red flags:

- Unusual engine noises

- Excessive exhaust smoke

- Sudden loss of power

- Check engine light activation

If you encounter these signs, cease NOS usage immediately and have your engine inspected.

| Risk Factor | Potential Damage | Prevention Method |

|---|---|---|

| Improper Fuel Mixture | Overheating, Detonation | Precise Fuel System Tuning |

| Excessive Nitrous | Piston Failure, Blown Head Gasket | Gradual NOS Increase, Stronger Internals |

| Poor Installation | Fuel Leaks, Electrical Issues | Professional Installation |

Legal Considerations and Racing Regulations

NOS use is subject to strict legal guidelines. The legality of NOS on public roads varies by state, with many prohibiting its use. Racing classifications also have specific rules regarding nitrous oxide systems, with some allowing its use and others prohibiting it entirely.

Emissions regulations significantly impact NOS legality. Many areas require vehicles to pass emissions tests. NOS can alter exhaust outputs, potentially causing failures. Racers must ensure their setups comply with local laws to avoid fines or disqualification.

Safety standards are critical when using NOS. Racing organizations mandate specific equipment and installation procedures. These rules aim to prevent accidents and protect drivers. Common requirements include:

- Fire-resistant lines and fittings

- Proper bottle mounting

- Clearly labeled shut-off valves

- Regular system inspections

Before installing NOS, it is essential to check your local laws and racing rulebooks. What is legal at one track might be banned at another. Always prioritize safety and compliance to enjoy the benefits of nitrous oxide without legal troubles.

Cost Analysis: Installation and Maintenance

For car enthusiasts, grasping the financial implications of a nitrous oxide system is essential. The cost of NOS kits varies significantly, influenced by the system’s complexity and power output. This section delves into the expenses related to NOS installation and maintenance.

Initial Setup Expenses

The initial costs for setting up a NOS system can vary widely. Basic kits start around $400, while advanced systems can exceed $2,000. Professional installation typically adds $200 to $500 to the total cost. For those inclined towards DIY, saving money is possible but requires mechanical proficiency.

| NOS Kit Type | Price Range | Installation Cost |

|---|---|---|

| Basic Kit | $400 – $800 | $200 – $300 |

| Intermediate Kit | $800 – $1,500 | $300 – $400 |

| Advanced Kit | $1,500 – $2,000+ | $400 – $500 |

Ongoing Maintenance Costs

Maintenance for NOS systems includes regular inspections, part replacements, and nitrous refills. Annual maintenance costs range from $100 to $300, influenced by usage frequency and system complexity. Nitrous refills typically cost between $3 to $5 per pound, with most cars needing 5-10 pounds per refill.

Refill and Replacement Frequencies

Nitrous refills are necessary after every few races or performance runs. Heavy users might require refills monthly, while occasional users may go several months without needing a refill. Components like solenoids and lines should be replaced every 1-2 years, costing $50-$200 depending on the part.

When planning for a NOS system, consider both the initial NOS kit prices and the long-term maintenance costs. While the power gains are significant, the ongoing expenses of nitrous refills and part replacements are critical to factor into your decision.

Comparing NOS to Other Performance Upgrades

In the realm of automotive performance enhancement, NOS is not the sole contender. We will examine its comparative standing against other prominent forced induction techniques.

Turbochargers vs NOS

Turbocharging leverages exhaust gases to drive a turbine, augmenting engine airflow. This method contrasts with NOS, which delivers power in brief, intense spurts. Turbos, while providing sustained power, often exhibit lag. NOS, on the other hand, offers immediate power boosts but is limited to short durations. Turbocharging incurs higher initial costs but obviates the need for refills, unlike NOS systems.

Superchargers vs NOS

Superchargers, driven by a belt, provide immediate power akin to NOS. They ensure consistent performance enhancements without the necessity for refilling. Supercharging, while more expensive than NOS, is less costly than turbocharging. It strikes a balance between cost and power output, making it a viable option in the performance spectrum.

Cost-Benefit Analysis

NOS excels in its adaptability and lower initial investment. It is ideal for racers requiring swift power surges. In contrast, turbocharging and supercharging offer more consistent power gains but at elevated costs. Your selection hinges on your driving habits, financial constraints, and performance aspirations. Each technology occupies a distinct niche within the automotive performance enhancement domain.

Leave a Reply