Direct Fuel Injection vs. Port Fuel Injection: Delivering Power in Different Ways

Direct fuel infusion and port fuel infusion are two unique strategies for conveying fuel to a gas-powered motor. While the two frameworks meet similar needs in providing fuel for ignition, they vary in how they achieve this assignment.

Port Fuel Injection: The Established Technique

Port fuel infusion, or multipoint fuel infusion, is the more customary and broadly utilized strategy. This framework infuses fuel into the admission complex close to the admission valves. The piston plunges, sucking in a hearty gulp of air. Right on cue, a high-pressure injector blasts a precise fuel shot directly into the cylinder, instantly creating a combustible cocktail ready to explode into action. Port fuel infusion offers great fuel atomization and dispersion, bringing about proficient burning and, by and large, motor execution.

Direct Fuel Injection: A More Precise Approach

Conversely, direct fuel infusion adopts a more straightforward strategy. Rather than infusing fuel into the admission complex, direct fuel infusion frameworks convey fuel straightforwardly into the ignition chamber. Fuel injectors mounted directly in the chamber head handle this critical task. By infusing fuel straightforwardly into the burning chamber, direct fuel infusion offers a few benefits.

One of the critical benefits of direct fuel infusion is its further development of eco-friendliness. By definitively controlling the timing and measure of fuel infused, direct fuel infusion considers better burning effectiveness, bringing about diminished fuel utilization. Moreover, direct fuel infusion frameworks can work at higher fuel pressures, improving fuel atomization and ignition productivity.

One more advantage of direct fuel infusion is expanded power yield. By conveying fuel straightforwardly into the burning chamber, the fuel is all the more successfully blended in with the approaching air, advancing a more complete and proficient ignition process. This prompts further developed motor execution, including expanded power and force.

Direct fuel infusion likewise offers better command over outflows. By definitively controlling the fuel conveyance, direct fuel infusion frameworks can upgrade the air-fuel combination for cleaner ignition, decreasing the development of unsafe toxins.

Notwithstanding, quite significant direct fuel infusion frameworks can be more difficult and costly to make than port fuel infusion frameworks. They require higher fuel tensions and further developed motor administration frameworks to work successfully.

In synopsis, direct fuel infusion differs from port fuel infusion by conveying fuel straightforwardly into the burning chamber rather than the admission complex. This approach offers benefits, for example, further developed eco-friendliness, expanded power results, and better emission control. However, it accompanies added intricacy and cost. The decision between direct and port fuel infusion relies upon variables, such as motor plan, execution prerequisites, and eco-friendliness objectives.

Here’s a table summarizing the key differences:

| Feature | Port Fuel Injection (PFI) | Direct Fuel Injection (GDI) |

|---|---|---|

| Location of Injection | Intake manifold | Combustion chamber |

| Mixing with air | Before intake valve | In combustion chamber |

| System complexity | Lower | Higher |

| Cost | Lower | Higher |

| Valve cleaning | Yes | No (requires additional systems) |

| Fuel efficiency (light load) | Lower | Higher |

| Power output | Lower | Potentially higher |

| Emissions | Higher | Lower |

Multipoint (Port Fuel) injection vs. direct injection. Are they really that different?

For years, internal combustion engines with electronic injection have been the norm in the automotive industry. This gasoline supply has allowed cars to be much cleaner and more efficient, but even this system has evolved to offer us increasingly powerful engines that use less gasoline and pollute less.

Nowadays the term “direct injection” is becoming increasingly common, leaving behind the famous “multipoint injection” that was so popular in the late 90s and early this century. But in order to understand how they work, we first need to know what fuel injection is.

The basis of the system

Electronic fuel injection is a system by which fuel is fed to the combustion chamber through an injector. Unlike the traditional carburetor, with the injection system, you can dose the amount of fuel used, making the engine more efficient.

Injection systems began at the same time as combustion engines. The first system of this nature dates back to 1881, but it was not until the middle of the last century, after the Second World War, that we began to see applications of this system in cars, mainly racing cars.

Multipoint injection

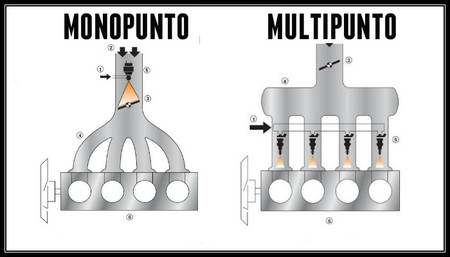

Injection systems originally used a single injector (sometimes two) for all cylinders placed in the intake manifold. This system, called single-point, supplies fuel to all cylinders simultaneously, creating the mixture before reaching the combustion chamber. very carburetor style. By adding one injector per cylinder, the fuel used can be better regulated, making the system much more efficient. However, the position of each of the injectors is also extremely important. In traditional multipoint injection, the injectors are still placed in the intake manifold, creating the air/fuel mixture before entering the combustion chamber.

Direct or indirect?

One of the great advantages of multipoint injection is that it can be used directly or indirectly, depending on the position of the injectors. As we said before, in the cases of indirect injection – which prevails today although it is changing rapidly – the injectors are placed in the intake manifold, so the fuel enters the combustion chamber already mixed with the air.

Having one injector per cylinder allows us to place them as close as possible to the combustion chamber, allowing both parts (air and fuel) to enter separately and mix inside the chamber, making the most of the fuel used. The computer regulates the amount of air that enters and supplies only the fuel necessary to make the required mixture, creating a much more efficient explosion.

It’s the same, but evolved

We need a direct injection system to be multipoint, but not the other way around. Having one injector per cylinder is essential to supply each cylinder with the necessary fuel directly, while in single-point systems the injector is in the intake manifold and allows it to supply all cylinders simultaneously.

By regulating the amount of fuel used more accurately, direct injection allows us to obtain more power and fewer pollutants since waste is less and efficiency increases considerably. Generally the computers of today’s cars are programmed to ask for a certain amount of fuel within different rpm regimes. The higher we climb the tachometer, the more air and gasoline is injected into the chamber.

As we can see, direct injection is an evolution of multipoint injection that finds a way to make the system more efficient by wasting less fuel searching for the perfect explosion to make the most of the engine’s performance.

Leave a Reply