Find out how your private jet’s engine works to fly like an expert

If 80 years ago it seemed impossible to fly at high speed from one continent to another, today it is commonplace. Most of the time, no one cares how a jet engine works, as long as it keeps us in the air all the way to our destination. But if you’re a little curious, we’ve got all the answers to your questions.

To do this, we asked Guy Ellis, author of Britain’s Jet Age From the Meteor to the Sea Vixen (Amberley Publishing, 2016) and Britain’s Jet Age From the Javelin to the VC10 (Amberley Publishing, 2016), to explain how it works. a jet engine.

Sir Isaac Newton’s Third Law of Motion

Everyone has had fun blowing up a balloon and releasing it to see it go in all directions. As we all know, it moves in the opposite direction to the airflow, an example of propulsion in its most rudimentary version.

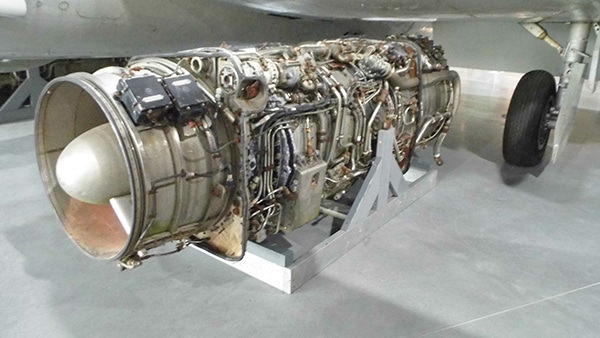

A jet engine, or turbojet, works on a similar principle. Air enters the engine through the inlet nozzle on the front. It is first compressed and pushed into the combustion chamber, where it is mixed with kerosene and ignited. The gases formed by combustion expand and are then expelled to the rear of the chamber. This backward movement of heated and expanded air exerts an equal and opposite force on the aircraft, which is then propelled forward. This is called “pushing”. When the gases are expelled, they pass through the turbine, a set of propellers mounted on a shaft. The gases thus rotate the shaft, allowing the compressor to be driven to allow a new influx of air.

John Barber patented and built the first gas turbine engine in Nottingham in 1792. It was a chain-driven engine with a compressor, combustion chamber, and turbine, all powered by wood, coal, or any other flammable substance. However, the heat-resistant materials needed to generate enough power to compress the air and gases and drive the chain and other engine components were unavailable at the time. Frenchman Maxime Guillaume encountered the same problem when he wanted to build his axial flow turbojet, patented in May 1921. In a 1926 article entitled An Aerodynamic Theory of Turbine Design, Alan Arnold Griffith set out the principles of an engine turboprop using an axial compressor equipped with blades, creating a more efficient airflow.

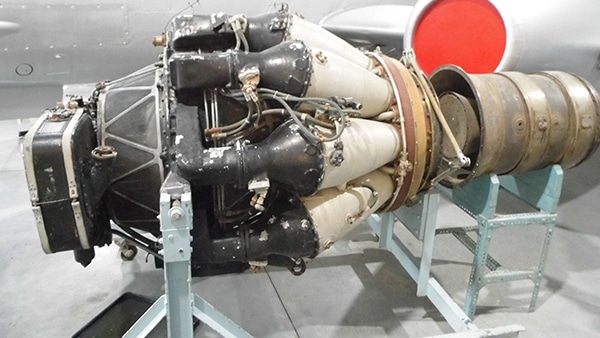

It was the same year that Frank Whittle developed his theory of using gas turbines to fly planes at altitudes and speeds that piston engines could not achieve. Patented in 1930, his invention was improved by the German Hans Von Ohain, who patented his turbojet in 1936. Working for Ernst Heinkel as part of a secret project financed by private funds, he developed a turbojet that flew for the first time on August 27, 1939, on a Heinkel He 178. It was Captain Erich Warstiz who made this first flight, marked by the loss of the engine shortly after takeoff due to a bird being sucked into the inlet nozzle. This is the first collision between a bird and a jet plane.

Largely ignored by the Reich Aviation Ministry, the development of the jet was hampered by the demand for “conventional” aircraft during the war. Less well known, a turbojet system with a fan was also used to equip the Italian Caproni-Campini CC2 aircraft, which in 1937 became the second jet aircraft in the world to complete its test flight successfully.

Planes in motion

There are four other types of jet engines besides axial and centrifugal turbojets. First, we have turboprops. In this type of engine, the exhaust gases drive a propeller, which is most efficient at speeds below 800 km/h. They mainly equip lighter aircraft and short-haul airliners. As technology has advanced, engineers have reduced the diameter of the thrusters, incorporating multiple scimitar-shaped blades to increase airflow through the compressor.

Next come the turbofan engines, which equip most modern airliners. These engines have an oversized fan that draws in much air that only partly passes through the compressor. Most of it bypasses the engine to the nozzle, where it is ejected, thereby increasing thrust without requiring more fuel. This type of engine also offers the advantage of being quieter.

The third type of turbojet was developed especially for helicopters. Called a free turbine turboshaft engine, it allows the helicopter blades to rotate at a different speed from the compressor. Since the rotor blades provide lift and directional control, they must maintain a constant speed even if the engine provides the additional power.

The final type of turbojet—called a ramjet—is a simple engine with no moving parts. Speed generates airflow, so an air launch system or a catapult must assist the takeoff. Acceleration then becomes dependent on thrust. This engine type primarily powers high-speed and rapid-combustion systems such as missiles.

Jet engines are lighter, have fewer moving parts, offer greater power, and are more fuel-efficient than piston engines. The Supermarine Spitfire reached an average top speed of 590 km/h. Britain’s first jet aircraft, the Gloster E28/39, produced 385 kg of thrust and reached a maximum speed of 750 km/h. The Concorde, finally, could produce a thrust of 17,260 kg per engine, with a top speed of 2,163 km/h.

Leave a Reply