It is an internal combustion engine with 4-stroke cycles (very similar to the Otto cycle) that is currently mainly used in hybrid vehicles given its high efficiency and reduced consumption due to its better use of fuel, although with somewhat lower powers.

It was developed in 1882 by James Atkinson and was born operating with the classic 4 strokes (intake, compression, expansion and exhaust) in one turn of the crankshaft, while Otto cycle engines require 2 revolutions of the crankshaft to carry out the same 4 strokes. .

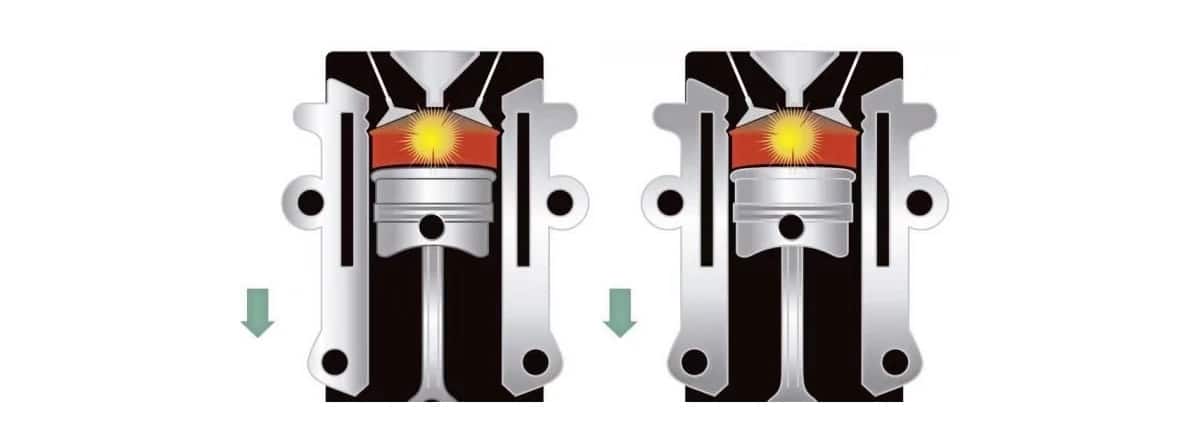

Currently, however, its concept has been modified, the fundamental difference with Otto cycle engines being the fact that during the compression stroke (approximately halfway through the cycle), the intake valves remain open, through the modification of the intake cams of the camshaft, thus generating an advantage due to a drastic reduction in the losses that the engine produces due to the compression of the mixture.

Operation of an Atkinson cycle engine

In an Atkinson cycle engine, the four strokes of a gasoline engine are also available, with intake, compression, explosion and exhaust. However, in this type of engine, the intake valve closes late during the compression process, which then decreases the actual compression, since the actual compression does not begin effectively until the intake valve has closed, causing This compression ratio can even be half that if the valve were closed before, as occurs in a traditional four-stroke Otto cycle.

With this modification, during the compression stroke (the moment in which the previously aspirated air-fuel mixture is compressed) and because the intake valves remain open, part of the mixture is returned to the intake manifold.

Some disadvantages of Atkinson engines

Indeed, Atkinson cycle engines have some disadvantages which, however, affect their mounting primarily in hybrid models today.

These engines suffer from lower thrust force on the piston head at ignition due to a smaller compressed mixture, resulting in lower overall power output compared to traditional engines.

A classic example of this issue is the 1,800 cc engine of the Toyota Prius, which is only capable of developing 100 HP of power.

Atkinson cycle engines generate maximum revolutions of 5,000 rpm due to their special timing configuration, therefore providing powers belonging to engines with smaller displacements and less performance.

Why are Atkinson cycle engines so useful in hybrid propulsion?

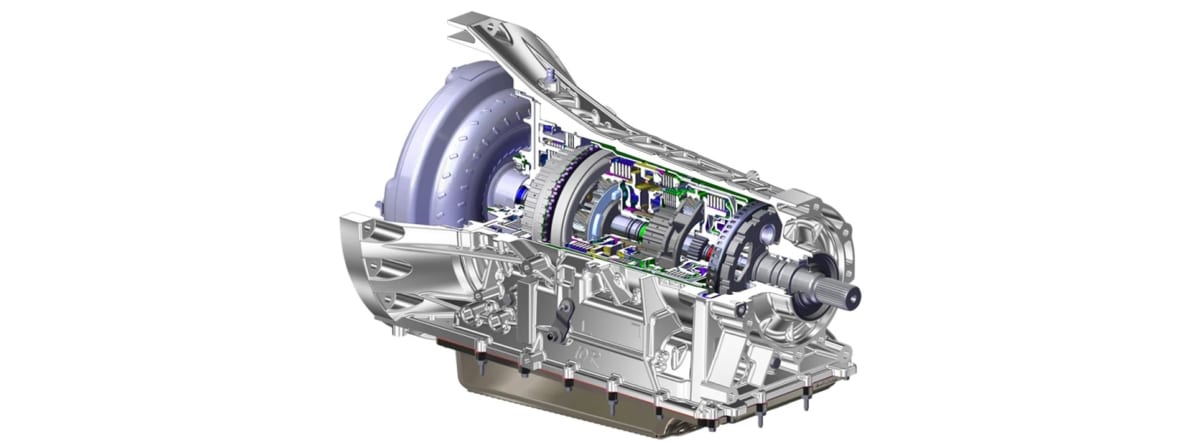

However, in a hybrid vehicle this power reduction is an advantage for the whole, since the lack of thrust is made up for by the electric motor and even better if it is combined with a CVT (Continuously Variable Transmission) gearbox that is already available. It is directly responsible for maintaining the optimal revolutions of the combustion engine constant.

Atkinson cycle engines excel in hybrid vehicles because their primary function aligns perfectly with hybrid design. These engines prioritize efficiency over raw power, allowing the electric motor to handle acceleration bursts. This focus on efficiency is why Atkinson cycle engines are so prevalent in hybrid marketing – combined with electric motors, they deliver the optimal balance of power and fuel economy that hybrid drivers expect.

It is evident that the Atkinson cycle manages to very directly increase overall efficiency, achieving low fuel consumption levels even with the valve timing modified with the most current technologies.

By delaying valve closure, this engine achieves higher compression ratios through earlier mixture explosions than standard Otto engines. This results in significant gains in thermodynamic performance and power output, all while maintaining its fuel efficiency advantage.

Korean manufacturers are betting very directly on this type of Atkinson cycle engine. They’re including them in more and more vehicles in their ranges. The list of models currently using this configuration type is very extensive. For example, we can cite the Toyota Prius, Ford Escape, Lexus RX 450h, Hyundai Sonata, Chevrolet Volt, KIA Niro, Hyundai Elantra, and KIA Forte, among many more.

Leave a Reply